In today’s sustainability-driven packaging world, recyclability is not just a claim — it must be traceable, verifiable, and tied to real material identification standards.

That’s where ASTM D7611, the global standard for plastic resin identification codes (RIC), plays a critical role.

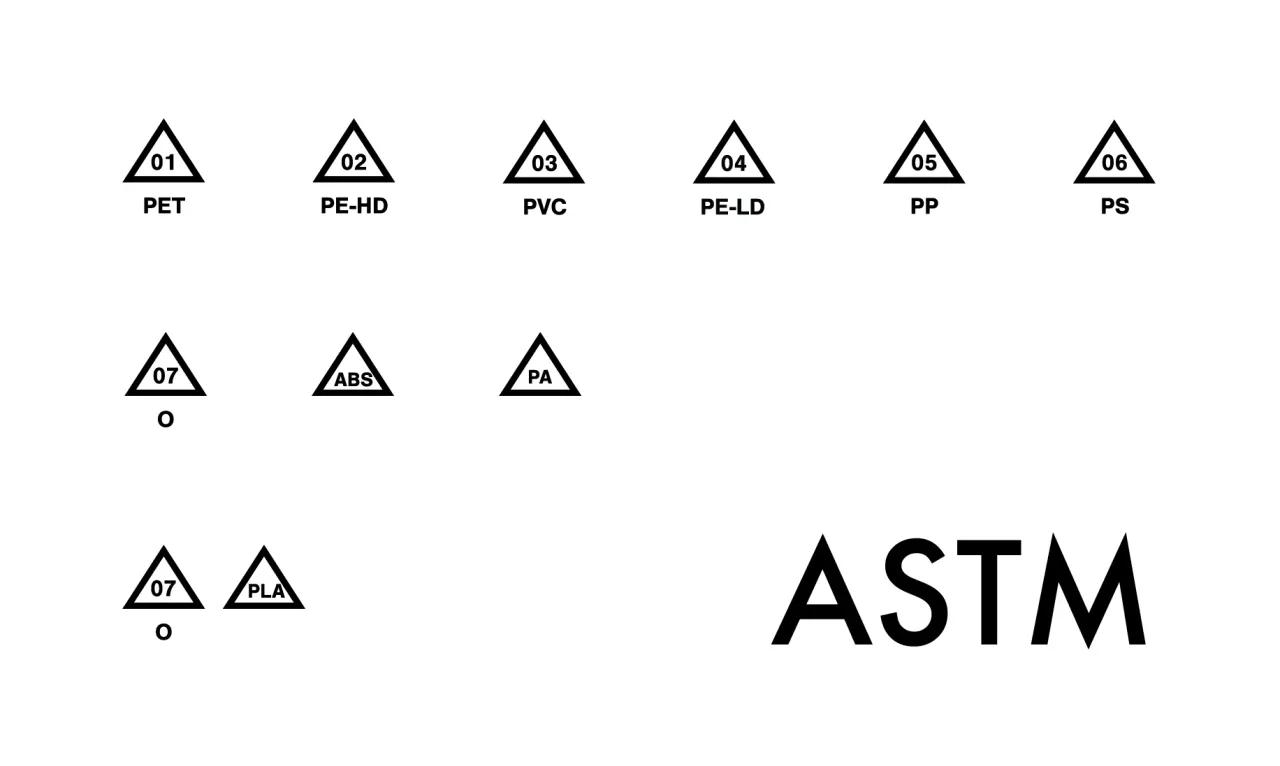

These small symbols — typically a number inside a triangle — determine whether a plastic product can be sorted, recycled, reprocessed, or returned to the circular economy.

At TP Plastic USA, we rely on ASTM D7611 as a key part of our transparency and sustainability framework, ensuring every stretch film, mailer bag, trash bag, plastic bag, and apron carries the correct resin code for seamless recycling within U.S. and global waste systems.

Understanding these codes isn’t just technical knowledge — it’s the foundation of responsible, modern packaging.

1. What Is ASTM D7611?

ASTM D7611 is the internationally recognized standard that defines the Resin Identification Codes (RIC) used to classify different types of plastic based on their polymer composition.

These codes ensure:

-

Uniformity in how plastics are labeled

-

Easier sorting at recycling facilities

-

Accurate identification for reprocessing

-

Clear communication between manufacturers, recyclers, and end-users

Each resin code corresponds to a specific polymer, such as:

-

#2 – HDPE

-

#4 – LDPE / LLDPE

-

#1 – PET

-

#5 – PP

-

etc.

For TP Plastic USA, the most important codes are #2 and #4, because these represent the majority of polyethylene films and bags used in flexible packaging.

2. Why Resin Identification Codes Matter for Circular Packaging

Even the most recyclable plastic can be lost to landfill if it’s not identified correctly.

A simple resin code directly affects:

✔ Sorting efficiency

MRFs (Material Recovery Facilities) rely on these codes to sort plastics by polymer type.

✔ Contamination risk

Wrong coding = contamination = entire bales rejected.

✔ End-of-life value

Properly labeled PE film has high demand in PCR markets.

✔ Consumer confidence

Clear labeling helps buyers understand disposal options.

✔ Retail compliance

Major retailers (Amazon, Walmart, Target) prefer products with correct resin labeling.

Resin codes are small details with massive impact on sustainability.

3. Understanding the Codes Relevant to TP Plastic USA

We focus on polyethylene-based products, which fall under these two key codes:

#2 – HDPE (High-Density Polyethylene)

Common in:

-

Trash bags

-

Grocery bags

-

T-shirt bags

-

Industrial liners

-

Plastic retail bags

Characteristics:

-

High strength

-

Excellent stiffness

-

Lightweight

-

Widely recycled across North America

#4 – LDPE / LLDPE (Low-Density & Linear Low-Density Polyethylene)

Common in:

-

Stretch film

-

LDPE mailer bags

-

Plastic bags

-

Transparent flat bags

-

CPE/TPE aprons (PE-based formulation compatibility varies by region)

Characteristics:

-

Flexible

-

High clarity

-

Excellent sealability

-

Strong performance at low thickness

-

Accepted by most U.S. film recycling programs

These two codes — #2 and #4 — represent the backbone of recyclable flexible packaging.

4. Why Polyethylene (#2 and #4) Is So Important for Recycling

Polyethylene is the most recyclable flexible plastic in the world.

♻ Easily melted & reprocessed

PE can be recycled many times without major polymer degradation.

♻ Compatible with PCR & PIR streams

Perfect for circular production using recycled content.

♻ Supported by U.S. and global MRFs

Both #2 and #4 are recognized in nearly all commercial recycling programs.

♻ High demand for recycled PE

Used in:

-

Film

-

Bags

-

Construction materials

-

Pallets

-

Secondary packaging

♻ Perfect for mono-material design

Ideal for sustainable packaging innovation.

This is why TP Plastic USA designs nearly all products around PE.

5. How TP Plastic USA Applies ASTM D7611 Across Our Product Lines

a) Stretch Film (LLDPE – Code #4)

Our stretch films are made from 100% PE structures:

-

Multi-layer LLDPE/LDPE

-

No PP, PVC, PET, or non-recyclable layers

-

Fully recyclable as #4 LDPE

Benefits:

-

Cleaner recycling

-

Better downgauging performance

-

Stronger circularity compliance for B2B buyers

b) LDPE Mailer Bags (Code #4)

TP Plastic USA mailers use mono-material LDPE, ensuring:

-

Accurate #4 labeling

-

Compatibility with retail recycling

-

Better end-of-life recovery

Even with printing or color masterbatch, recyclability remains high.

c) HDPE/LLDPE Trash Bags (Code #2 or #4)

Depending on material type:

-

HDPE bags = #2

-

LDPE bags = #4

-

Recycled-content blends remain within these categories

Star-seal and gusset designs maintain single-polymer structure.

d) Plastic Bags (HDPE/LDPE – Code #2 or #4)

Retail bags, grocery bags, and flat bags follow strict RIC labeling:

-

Ensures correct sorting

-

Increases bale purity

-

Reduces downstream contamination

e) CPE/TPE Gloves

CPE/TPE formulations align with PE recycling in many regions, providing:

-

Clear end-of-life pathways

-

Higher acceptance in film recovery streams

While resin code labeling depends on regional rules, the PE chemistry supports recyclability.

6. How ASTM D7611 Supports Customer Sustainability Goals

1. Easier ESG & sustainability reporting

Resin codes provide transparent material disclosure.

2. Simpler recyclability claims

Brands can confidently state:

“Made from recyclable PE (#2/#4).”

3. Better compliance with major retailers

Amazon, Walmart, and Costco prefer recyclable PE packaging.

4. Lower environmental impact

Correct coding increases the likelihood that the product will be recovered and reprocessed.

5. Improved circular manufacturing

RIC helps maintain high PCR and PIR quality.

7. The Future: More Brands Will Require RIC Labeling

As regulations evolve (U.S. states, EU packaging directives, Canadian EPR laws), resin identification will become mandatory for:

-

Online retail packaging

-

Mailers

-

Film-based products

-

Trash bags

-

Food-service bags

-

Industrial packaging

TP Plastic USA is already aligned with these requirements, simplifying compliance for our U.S. customers.

Resin Codes Are the Small Label That Enables Big Sustainability

ASTM D7611 may seem like a small detail, but it plays a major role in building a circular packaging system.

By applying clear, accurate resin identification codes (#2 and #4), TP Plastic USA ensures that:

-

Every product is easier to recycle

-

Every film and bag supports circularity

-

Customers can meet retailer and regulatory requirements

-

Sustainability is measurable, not just a marketing claim

From stretch film to mailer bags, trash bags, plastic bags, and aprons —

resin transparency is part of our responsibility to the environment and to our customers.